What is Brake Lining? What Does Brake Lining Mean?

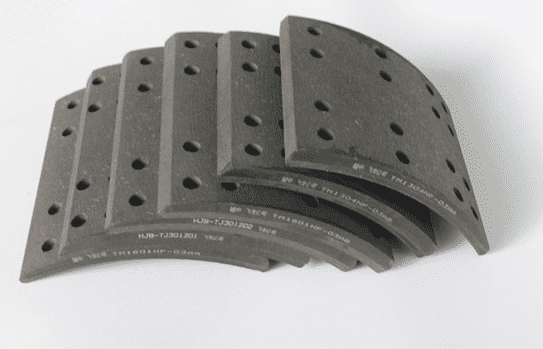

Brake lining are generally composed of a bottom plate, a bonding heat insulation layer and a friction layer. The heat insulation layer is composed of poor thermal conductivity materials and reinforcing materials. The friction layer is composed of reinforcing materials, adhesives and fillers (friction performance modifiers).

For brake linings, the most important thing is the choice of friction material, which basically determines the braking performance of the brake lining.

The basic quality requirements of brake pads are: wear resistance, large friction coefficient, and excellent heat insulation performance.

According to different braking method, brake lining can be divided into disc brake pads and drum brake lining.

According to different manufacturing materials, there are three types: asbestos, semi-metal and organic (NAO).

1. The main advantage of asbestos sheet is cheap. Its disadvantages are: it does not meet modern environmental protection requirements; asbestos has poor thermal conductivity.

2. Semi-metallic compound brake lining: mainly use rough steel wool as reinforcing fiber and important compound. The main advantage is: high braking temperature due to its good thermal conductivity. The disadvantage is that a higher brake pressure is required to achieve the same braking effect, especially in a low-temperature environment with a high metal content, which will wear out the brake disc and generate greater noise.

3. Non-asbestos organic NAO brake pads: mainly use glass fiber, aromatic polyamide fiber or other fibers (carbon, ceramic, etc.) as reinforcement materials.

The main advantages of NAO discs are: maintaining good braking effect regardless of low temperature or high temperature, reducing wear, reducing noise, and extending the service life of brake discs.

Post time: Nov-23-2020