Installation inspection preparation:

Single chamber: check to ensure that the push rod of brake chamber is in the initial position; double chamber: apply and maintain the brake air pressure above 0.6MPa to make the push rod of brake chamber in the initial position.

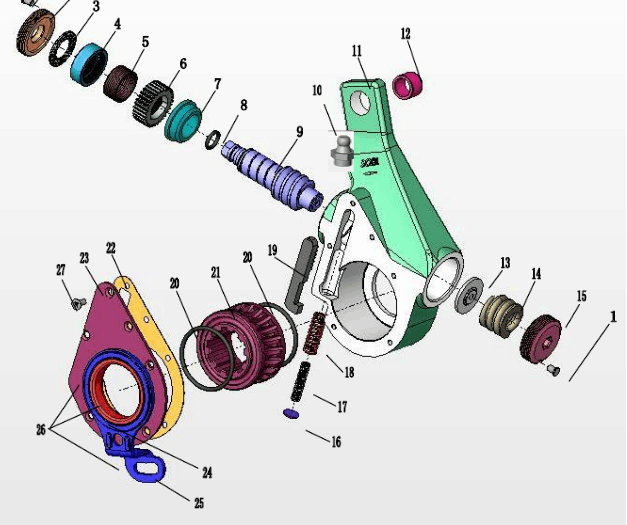

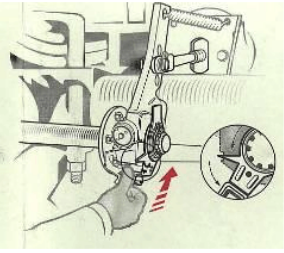

Release the brake (aftertaste of brake chamber push rod), and remove the invalid adjusting arm. Remove the sundries on the camshaft spline and install the automatic adjustment (pay attention to the direction of the arrow on the nose should be forward)

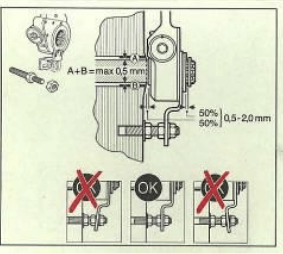

2.The hole on the adjusting arm and the hole on the push rod fork can’t match. Use a wrench to adjust the hexagon head to make it aligned.

3.Use gasket or other tools to make the adjusting arm in the position shown in the figure.

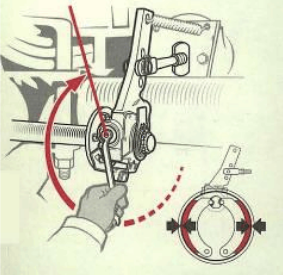

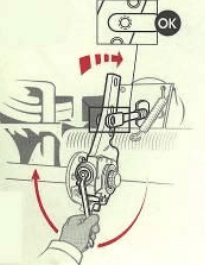

4.Push the control board by hand in the direction of the arrow on the arm until it can not be pushed by hand, and fix the control board.

5.Use a wrench to adjust the hexagon so that the friction plate presses the brake drum tightly. In this adjustment process, the handle is: it is very easy to rotate at first, and it can’t be adjusted at last no matter how much force is used. If you hear a click when you adjust hard, it means that the direction is reversed.

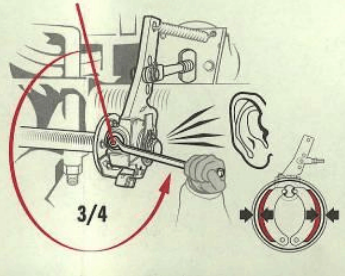

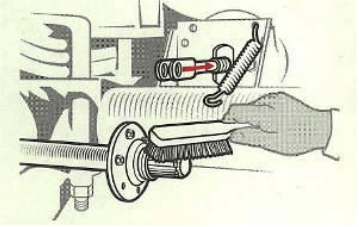

6. On the basis of the fifth step, reverse adjust 2-3 circles (adjust one circle and click once), and the adjustment is completed

When the brake air path is connected, apply 10-20 times of complete braking, the brake clearance will be automatically adjusted to the normal range, and the installation is completed.

Note: whether the self-adjusting function of the adjusting arm is normal or not can be determined by observing the automatic rotation of the worm hexagon at the end of each braking.

Post time: Mar-15-2021