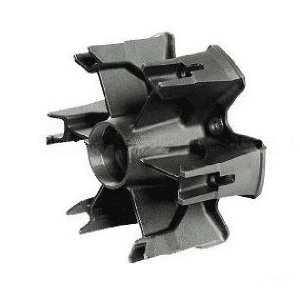

mercedes brake drum

How to repair brake drum?

The braking force of the vehicle is generated by the friction between the brake drum and the brake shoe friction plate, which makes the vehicle slow down or stop. After long-term use, the brake drum is worn, resulting in the groove and strain on the inner surface of the brake drum. When the roundness deviation of the brake drum exceeds 0.25 mm, there is a deep groove on the working face, and the linear deviation from the hub bearing exceeds the specification, boring shall be carried out. When boring the brake drum, the brake drum and the wheel hub should be assembled together and positioned by the outer race of the inner and outer wheel hub bearings. Boring can be carried out on special equipment or lathe. The cylindricity deviation of the cut brake drum shall not be greater than 0.075mm, the coaxiality deviation with the wheel axis of the car shall not be greater than 0.025mm, the size difference between the left and right wheel brake drums shall be less than LMM, and the inner diameter shall not exceed the maximum allowable repair size. During the inspection, if cracks are found on the brake drum or the inner diameter has exceeded the maximum allowable repair size, it shall be replaced.

Have you seen Benz's first flat floor truck? It's really cool!

When it comes to flat floor trucks in Europe, in fact, in addition to the Renault AE (later renamed magnon) model, Mercedes Benz launched Actros MP1 model in 1996 as the backbone of the brand in exploring the future development of truck comfort.

Introduction of Mercedes Benz Actros MP1

In 1996, the trunk logistics transport models in European truck market are basically in the developing stage. Even Scania streamline, Duff 95xf and Mann F2000 series models, which are famous for their comfort, have not launched flat floor models with avant-garde comfort.

When it comes to this, it may be mentioned that Volvo FH12 has started the development trend of flat floor trucks in Europe, but compared with Actros MP1 series models, this model has improved in comfort. It was not until 1998 that the 700mm wide sleeper configuration with higher comfort was introduced on the original basis. However, the obvious bulge on the floor still has an impact on the basic comfort.

At that time, in order to enhance the development opportunities of the brand in the European market, Mercedes Benz launched the historic Eurocab cab based on the old generation SK Series in the late 1980s, and then the megspace cab used in Actros MP1 series, which was born in 1996, can really become an epoch-making significance. In addition to comfort, intelligent power chain is also the lifeblood of the brand in the world logistics and transportation market.

Next, we will introduce the overall advantages of Mercedes Benz's first high-end model in terms of comfort, power, etc.

Simple appearance with low wind resistance concept

The flat floor cab used by Mercedes Benz Actros MP1 is named megspace, which was not changed until the birth of the fourth generation model in 2011. However, in the period before 2010, the comfort of this model has laid a solid foundation for the development of Actros MP2 and MP3.

Purely from the perspective of modular production concept, this model has more improvements in reducing R & D costs, which is most obvious in China's independent brand jh6 excellent version and pilot version. It can meet the needs of driver users with different needs and development environments as much as possible.

Middle net adopts a simple plane design, with a standard size Trident star logo in the middle, which has been extended to the design of Mercedes Benz's new generation Axor series of medium and short distance logistics transport models. Although the overall appearance seems simple, but including the cab roof, low wide body bumper and other components still use a very detailed wide body design.

At that time, the new models didn't have the aba5 series active driving assistant safety system, and the single side double lens was the key to improve the active safety.

Actros MP1 is the key to brand creation. However, the new generation of Actros MP1 did not use split bumper at that time. The integrated design has a clear sense of hierarchy, and it is slightly cumbersome to replace lighting components later.

It is worth mentioning that the foreground lights of this model are placed on the ground floor, while the fog lights and auxiliary steering lights are placed on the top. Of course, this design is also a key step for Mercedes Benz to explore the active safety of the vehicle

Comparing the two cabs, it is not difficult to find that the configuration of megaspce is better in terms of comfort, and there is a multi open storage compartment behind and above the wheel eyebrow, which is convenient for cardmate to place more items with the car during long-distance driving. In view of the actual needs of trunk logistics transportation, the wide body spoiler cover and side skirt of the vehicle also play an excellent disturbing effect.

The real sense of flat floor cab is very comfortable

In the European Truck camp at that time, Mercedes Benz has begun to move towards the intelligent direction. Although the four-way steering wheel adopted has no multi-function buttons, its unique multi-angle adjustment design is still reflected in the new generation of vehicles today.

The instrument panel adopts a simple mechanical design, with speedometer and tachometer on both sides, mileage, fuel consumption and other basic indication functions in the center. The monochrome LCD screen in the center reflects the brand's breakthrough in electronic intelligence.

Cruise speed control, audio-visual entertainment adjustment and other function buttons are set on both sides of the instrument panel, which has been designed in the internal position of the steering wheel in the second generation vehicles. It can be found from the details that this car aimed at the actual situation of European cross-border transport drivers' parking rest at that time, and also provided the parking firewood and heating of webaston, which improved the driver's indoor comfortable life in the cold environment in winter.

Since it is a new generation of Mercedes Benz, the comfort of the main driver's seat is also very prominent. In addition to damping adjustment and other functions, it also has two-way lumbar support and a strong wrapping backrest. This is worth learning and using for reference even in many high-end domestic models today.

This model uses a very simple center console and a nearly flat design to provide more practical and convenient conditions for drivers to park and rest. Even in today's latest generation of models, it still gives full play to such comfort.

The central control area is equipped with manual air conditioning, simple audio-visual entertainment system, and multiple function buttons such as skylight, power supply and speaker adjustment are set above.

This model has made great progress in intelligent operation while moving towards comfort. For example, the shift integration is placed on the right side of the main driver's seat. This compact design occupies less indoor activity space.

The shift lever adopts push-pull design, and the rear is equipped with multi-function shift operation, which is simple and practical, and has obvious characteristics. Although it seems to be an intelligent shift operation, this car is also equipped with clutch pedal, which is convenient for the driver to shift.

The comfort of the flat floor cab is very distinct in this model. Besides a diversified storage space under the sleeper, the flat floor space is equipped with a simple refrigerator and built-in high storage space, so that the use space of long-distance driving can be more fully exerted.

The co driver also adopts a multi angle adjustable seat and an adjustable foot pedal at the front, which provides a more comfortable experience for the driver to park and rest. The rear sleeper has adopted a wide body design. Compared with Volvo FH12, it really meets the actual needs of truck drivers for long-distance driving.

The upper berth adopts a compact foldable design, and the outer side is also provided with a net pocket to play a fixed role. However, it should be mentioned here that European freight vehicles are equipped with a driver, so the original factory can also choose the fixed storage box in the upper berth position.

Om501 V6 engine era model

From Actros MP1, which was born in 1996, to MP3 series, Mercedes Benz has adopted this most epoch-making om501 series engine, providing 350, 400, 420 horsepower and other power configurations, fully meeting the needs of medium and long-distance trunk logistics transportation.

Until the end of 2019, this power will still provide power support for various transport vehicles and construction machinery meeting Euro 5 and below emission standards for China and many countries in Southeast Asia.

However, in the development process of the times, Mercedes Benz launched a new generation of om470, 471 and 473 power chains in 2011. Compared with the previous om502 V8 engine dedicated to heavy haul transportation, the modular new ternary configuration is also the beginning of lightweight, energy saving and emission reduction in the future development.

In addition, the intelligent shift transmission of powershift not only achieves phased results in reducing labor costs, but also determines the direction for the future development of unmanned driving.

Conclusion:

As time goes by, it has been 24 years since the first generation of Mercedes Benz Actros MP1 Series Tractor was born. During this period, European trucks represented by this brand have been in the forefront of innovation and development. In addition to making achievements in comfort, energy conservation and emission reduction, active and safe driving is also the key to the long-term development of this kind of vehicles

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.