MBP 16t german type axle with slack adjuster

|

Problem |

Possible causes |

Removal method |

|

Easily spoil the Wheel stud |

1.Improper tightening torque | Tighten to the required torque |

|

|

2.Severely overload | Do not overrun the Rated Axle load |

|

|

3.The wheel rim of the wheel distorted, or irregular bolts distribution | Replace the steel ring |

|

Excessive wear of the tires |

1.The air pressure inside the tire is improper | Inflate the tire with proper air pressure |

|

|

2.The U-bolt is loose; or some suspension parts worn out distorted, or moved; so the distances from two ends of the axle to the traction pin, or distances between two axles not equal to each other | Adjust the suspension system to make the two ends of the axle are parallel; replace the worn out or distorted parts; tighten the U-bolts |

|

|

3.The wheel rim distorted | Replace the wheel rim |

|

|

4.The tires are unmatched | To get proper tires as required |

|

|

5.The bearing is too loose | To regulate the bearing as required |

|

The brake is pulling |

1.The return spring fails | Replace the return spring |

|

|

2.Lag movement of the emergency relay valve or the air chamber | Check and repair the valve or the air chamber |

|

|

3.The air circuit system is leaking | Check and repair |

|

|

4.The slack adjuster is improperly regulated | Regulate the slack adjuster |

|

|

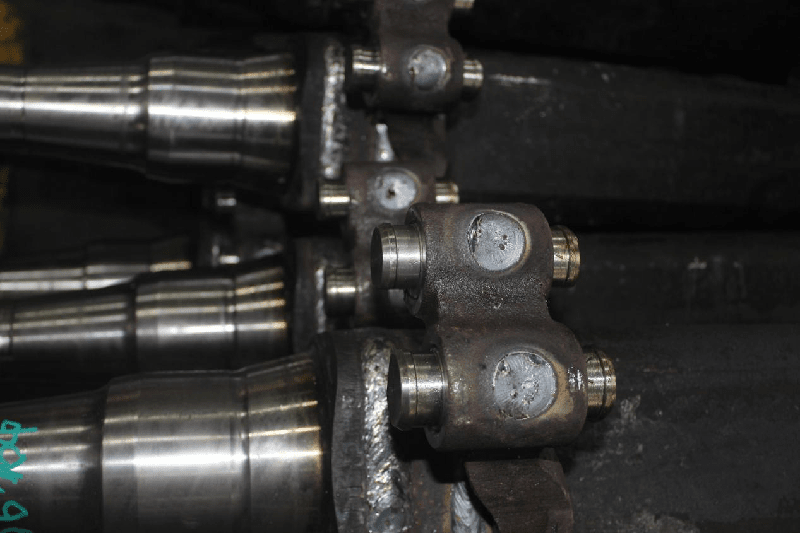

5.The camshaft is seriously worn out | Replace the camshaft |

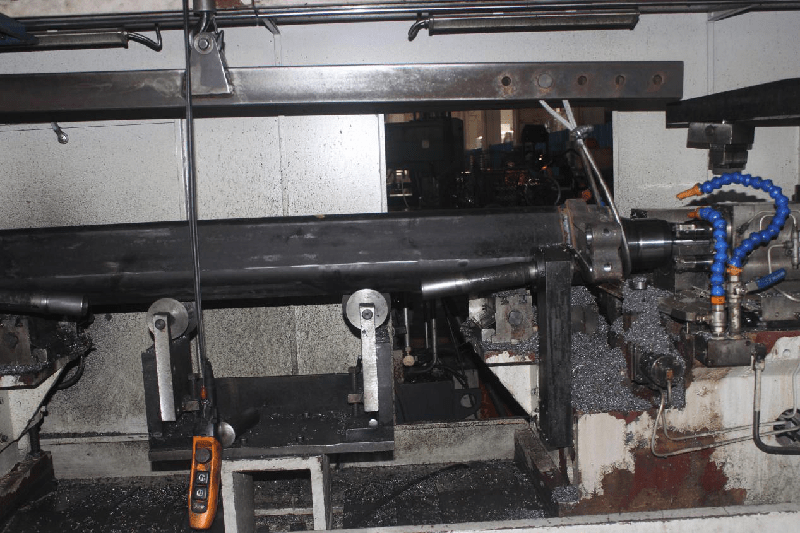

Operating Instruction on Installation 16 ton MBP axle

1.Welding the spring plate on the axle

The spring seat is the bend of stress in the whole Axle, also high quality welding of the spring seat and the Axle is very important. The welding quality directly affects the capability of the Axle.

Attention please when you weld the spring plate on the Axle:

(1) . The spring seat should be kept close to the upside & downside of Axle beam. It should be repaired then proceed further if their joint is not close enough.

(2) The position of the spring seat on the axle beam should be met the requirements with orientation center.

(3) The welding ground wire should be connected on the axle beam only, it’s not allowed to connect on any other parts of the axle through wheel rotation, so as to avoid the damage owing to striking fire caused by the current of bearing.

(4) Welding can only be carried out on the side of the axle vertically. It is not allowed to weld on any other places.

2.Wheel installation

A.Check the wheel rim, and it should be satisfied below requirements:

(1) The tolerance of the Spoke’s flatness should be no more than 0.15mm.

(2) The tolerance of the position of stud hole should be no more than 0.30mm.

(3) The central Hole of 10-hole Wheel is 281 +0.3.

B.Installation procedure of the Wheels:

(1) Check the joint face between the axle and the wheels, cleanup sundries such as dirt and burrs.

(2) Tighten the wheel nut diagonally to Rated Torque value with suitable nut sleeve and torsion spanner. If it’s wheel stud for TRILEX, tighten the nut along the wheel continuously.

C.Notice:

(1) If it’s 10 studs (10-M22*1.5 ISO) symmetrically put 2 pieces of Wheel Bolt Bush among the 10 Studs of each wheel when installing the wheel.

Special notice: The Wheel Bolt Bush is very important to the safe use of the Wheel Stud, make sure not to lose them when carry out installation or replacement.

(2) Tighten the Nut on diagonally while the wheels leave the ground.

(3) The Nut of In-board Brake Drum is self-locking, it should be replaced after assembled and disassembled for 2 times.

(4) The Wheel rim and the Brake drum cannot collide each other. The radial clearance between the Wheel rim and the brake drum should be more than 3mm.

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.