MBP 14T german type axle

Malfunction reason & Troubleshooting for axle

|

Problem |

Possible causes |

Removal method |

|

Poor braking effort |

1.Excessive clearance between the Brake block and the Brake drum | Regulate the clearance |

| 2.There is grease on the surface of the Brake linings | Clean the grease or replace the Brake lining | |

| 3.The stroke of the Push Rod in Air Chamber is too big | Adjust push rod stroke to :20-28mm | |

| 4.The Camshaft cannot turn freely | Check work position and sleeve condition | |

| 5.The air pressure of the Brake system is insufficient, or pressure boosting too slow | Check and repair the air circuit control system | |

|

The wheel hub is overheat |

1.Bearing is over tightened | Readjust the bearing |

| 2.The bearing is worn out | Replace the bearing | |

| 3.Insufficient lubrication to the bearing, or too much grease inside the hub cavity, or inferior grease | Fill sufficient and good quality grease | |

|

The bearing spoiled too fast |

1.Severely overload | Do not overrun the rated axle load |

| 2.The Bearing is too tightened or loose | Adjust it as required | |

| 3.Insufficient grease for the bearing | Fill proper grease | |

| 4.Impacting strength is too high | Try to avoid impacting to the Axle |

| Leading Index comparation | |||||||

|

Test item |

Quenching surface hardness |

Tempering surface hardness |

Tempering inside hardness |

Yield strength |

|

Grain size |

Decarburization layer |

|

Testing instruments |

Brinell hardness tester |

Brinell hardness tester |

Brinell hardness tester |

Material tensile testing machine |

Metallurgical microscope |

||

|

Testing standard |

Vickers hardness tester |

GB/T 13239-2006 |

GB 6394-2002 |

GB 224-2008 |

|||

|

Index requirement |

≥270HB |

210-260HB |

210-260HB |

≥620MPa |

≥20% |

≥ grade 5 |

≤0.25mm |

|

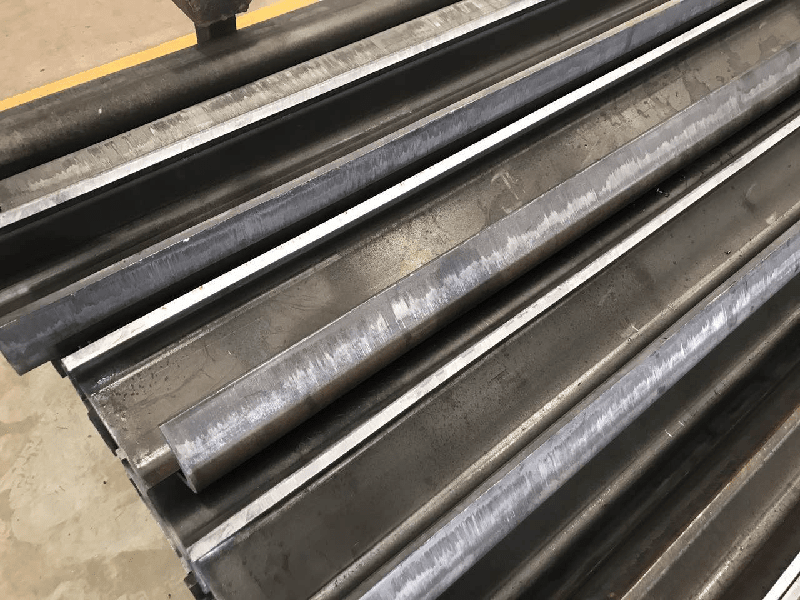

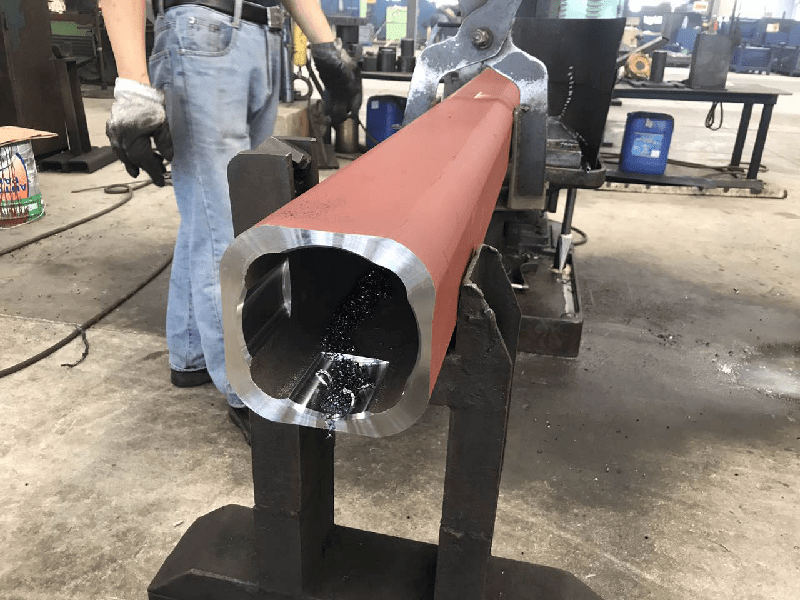

MBP axle tube |

350-480HB |

210-250HB |

240-250HB |

638-710MPa |

20%-21% |

7.5-8.5 |

0.11-0.18mm |

|

Competitor 1 |

/ |

193-223HB |

252-267HB |

708-790MPa |

16.5%~18.5% |

7.5-8.5 |

/ |

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.