How to maintenance trailer air suspension and pneumatic system

Pneumatic system after first load and ride then per six month:

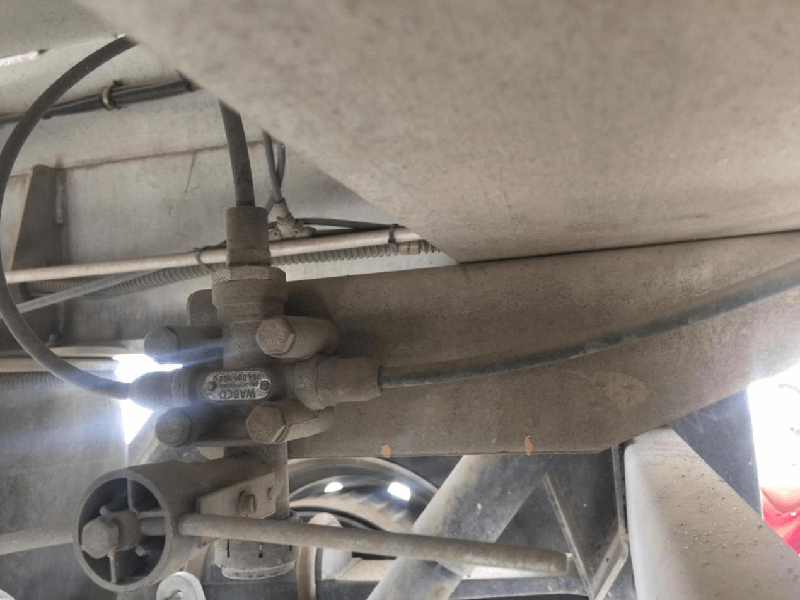

Check and guarantee the cleaning and integrity of air pipe;

Check the gas tightness of valve and pipeline fittings and check whether their installation is fastening and free of damage. Check whether the valve and fittings and fasteners are free of damage and locked tightly, and whether the FH value is improper;

Check whether the adjustment lever of altitude valve is fastening and free of damage. In balance, the angle between the valve body rocker and straight-bar is specified in the installation manual for Height control Valve.

Shock absorber after first load and ride and per three months:

Check the fastening conditions for the upper and lower parts of the shock absorber. The tightening torque is specified in the P22 Torque Table for Important Fasteners.

Check the leak tightness of shock absorber. Should change the shock absorber during appearing of oil leakage.

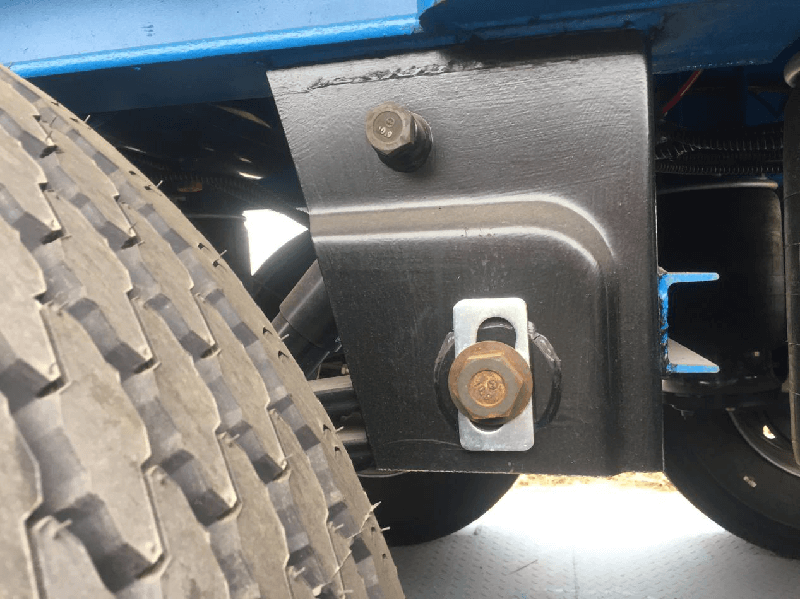

Locking parts of the vehicle axle after first load and ride and per three months:

Check the fastening conditions for lock bolt and nut of the vehicle. Lock the nut diagonal alternately. The tightening torque is specified in the P22 Torque Table for Important Fasteners.

Check the weld joint between the vehicle axle and upper and down plate. If any explosive welding appears, should weld it again immediately.

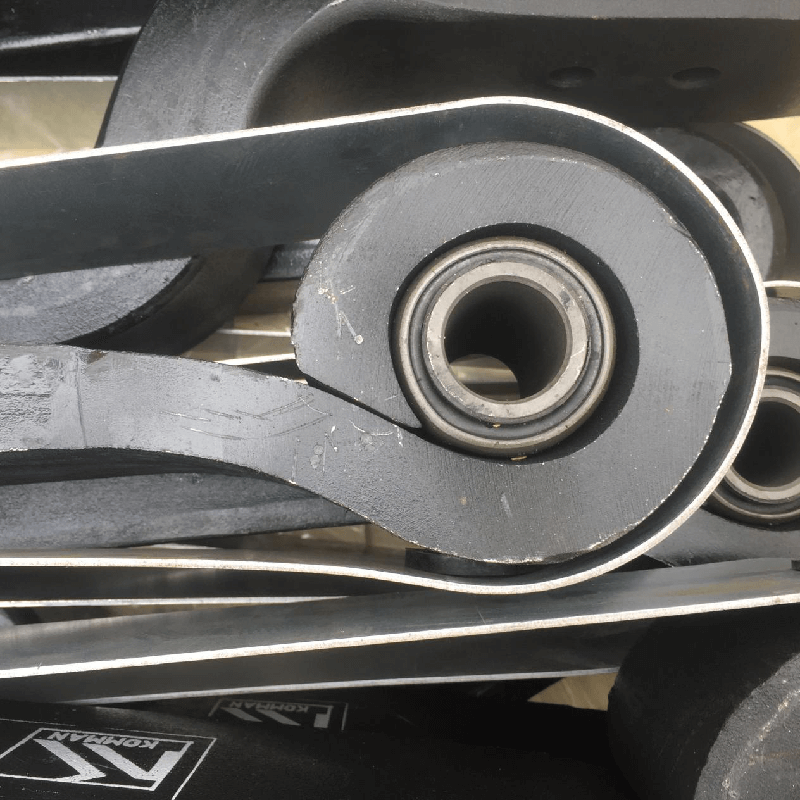

Stud shaft(oriented arm shaft, support beam axle) after first load and ride and per three months:

Sleeve checking: slightly drive the trailer and make it moving front and back or use a lever to pry one end of the oriented arm(support beam) closed to the oriented arm shaft. At this moment, the spring beam should be free of loosing.If the fasteners are with loosing phenomenon, the oriented arm shaft(support beam axle) may be damaged.

Check the wearing condition for the wearing-resistant plate inside of the support. If it is worn severely, the wearing-resistant plate should be changed.

Check the fastening conditions for lock nut of the oriented arm shaft(support beam axle).

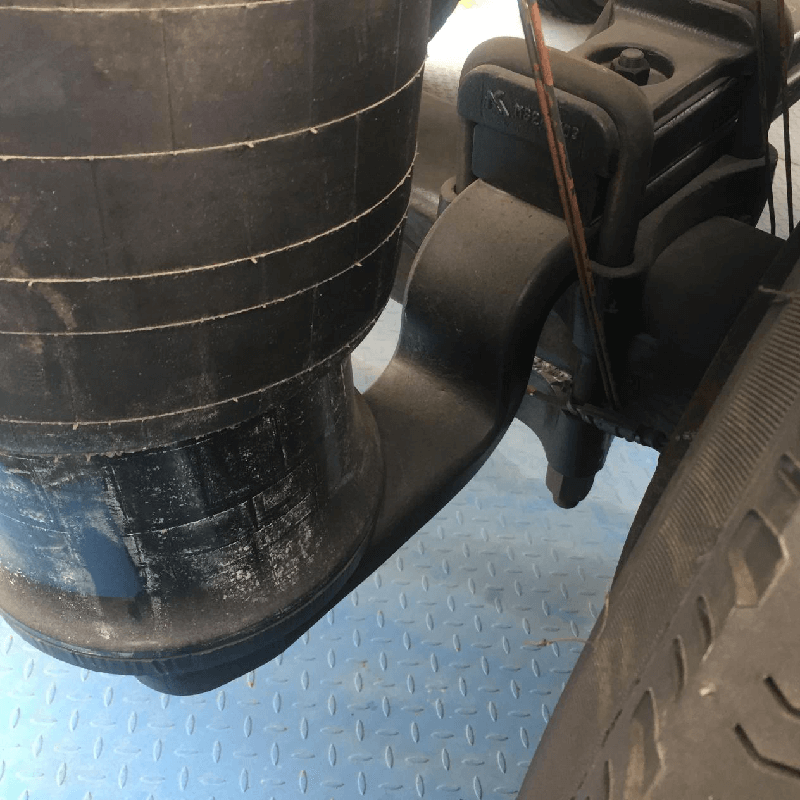

Limit steel rope or limit:

Check the limit steel rope or limit belt and their accessories. If required, should change them.

Test for the regulating mechanism(if have) after first load and ride and per month:

Check whether the welding spot between the adjusting plate and sleeve appears explosive welding. If any explosive welding appears, the adjusting plate may be shifted. Should re-adjust the axles distance.

Check the wearing conditions of oriented arm shaft, front hanger shaft sleeve. If required, should change it timely.

Air tank:

Check the service conditions of the drain valve on the bottom of air tank. If any blocking occurs, should change it. (if frost days appear, should check it one time per two weeks.)

The inspection for the suspension mounting height FH value after first load and ride and per three months:

The FH value of the trailer is set up before it leaves the factor. The clients must perform regular calibration according to the FH value specified by the trailer manufacturer. The FH value may be adjusted by regulating of altitude valve adjustment lever so as to keep it in accordance with the value during leaving factory.

Notice: If the vehicle runs under severe conditions, the times of maintenance should be increased.

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.