High Quality Axles For Sale - Teach you how to adjust to prevent brake weakness – MBP

High Quality Axles For Sale - Teach you how to adjust to prevent brake weakness – MBP Detail:

About the automatic adjusting arm, we have done some knowledge popularization work, but there are still many car owners lack of understanding of the automatic adjusting arm. So MBPAP will explain some knowledge about the automatic adjusting arm in several issues.

What we need to pay attention to here is that we have mentioned the regulations on the mandatory installation of automatic adjusting arm for vehicles. It does not mean that all vehicles in operation must be equipped with automatic adjusting arm. Instead, it means that new vehicles are required to be equipped with automatic adjusting arm by the manufacturer. Otherwise, it is not allowed to be sold outside the factory. Many vehicles are equipped with automatic adjusting arm, and the car owners lack proper understanding of the automatic adjusting arm. Some car owners have poor matching after using the automatic adjusting arm. Coupled with the high cost, it is easy to go back to the old way of choosing manual adjusting arm.

Installation issues

1. The axle factory didn’t design a suitable fixing pin for the control arm of the self-adjusting arm according to the technical requirements, resulting in the early wear of the connecting sleeve on the self-adjusting arm due to the unadaptability of the pin during the use of the self-adjusting arm, and finally leading to the failure of weak braking of the vehicle.

2. After the parameter matching between the self-adjusting arm and the brake, the axle factory suddenly changed the brake material and brake related parameters, resulting in the problem of a large number of vehicle brake weakness in the user market.

Sudden change of brake material and parameters will lead to weak braking

3.In the process of assembling the self-adjusting arm, the axle factory removed the connecting sleeve of the self-adjusting arm, which caused the brake gap of the rear axle of these vehicles in use to be too large and the brake was weak. At the same time, the front axle suffered the brake force of the whole vehicle for a long time, resulting in the front axle brake heating and abnormal wear of the friction plate.

Maintenance issues

1.The logistics company, six 6×4 brand tractors in operation, repeatedly occurred in the middle and rear axle brake lock failure. After on-site inspection, it was found that the main reason was that the user’s maintenance was not timely, resulting in the camshaft, shoe and shaft sleeve and positioning pin were rusted and stuck, and the brake shoe and brake drum were worn.

2.A logistics company in Xiaogan, Hubei Province purchased a batch of heavy-duty trucks. During 13 months of operation, the internal cavity of the self-adjusting arm was never filled with grease, resulting in the grease drying of the internal cavity of the self-adjusting arm, water corrosion, and the self-adjusting arm function failure. At the same time, it also led to the brake weakness of these vehicles.

3.A batch of light trucks of a certain brand have the fault of short service life of rear axle friction plate of 4 vehicles for a long time in use. After on-site inspection, it is confirmed that due to the quality problem of the brake master cylinder, the rising speed of rear axle brake air pressure is much faster than that of front axle brake air pressure, resulting in serious heating of rear axle brake and abnormal wear of friction plate.

Other issues

1.Tractor in domestic market is equipped with automatic self-adjusting arm, while trailer is equipped with manual adjusting arm. In actual use, the tractor brake temperature is too high and the service life of friction plate is too short.

2.The truck market (especially off-road vehicles) often has the problem of weak braking. After on-site inspection, it is confirmed that the push rod in the air chamber is not reset properly, so the self-adjusting arm can not work normally, resulting in large braking clearance, resulting in the problem of weak braking.

3.A batch of 8 × 4 heavy trucks equipped with self-adjusting arm in a heavy truck company had the problem that the brake temperature of the third axle and the fourth axle reached 300 ℃ when driving to 25000-30000 km. After on-site inspection, it was confirmed that the brake clearance of the third axle and the fourth axle was normal. However, it was found that the camshaft had basically stood up when the friction plate wear was 5-6mm, which caused the brake shoe reset very slowly, and there was the problem of brake drag The service station adopts the replacement of the roller with larger diameter to eliminate the fault.

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.

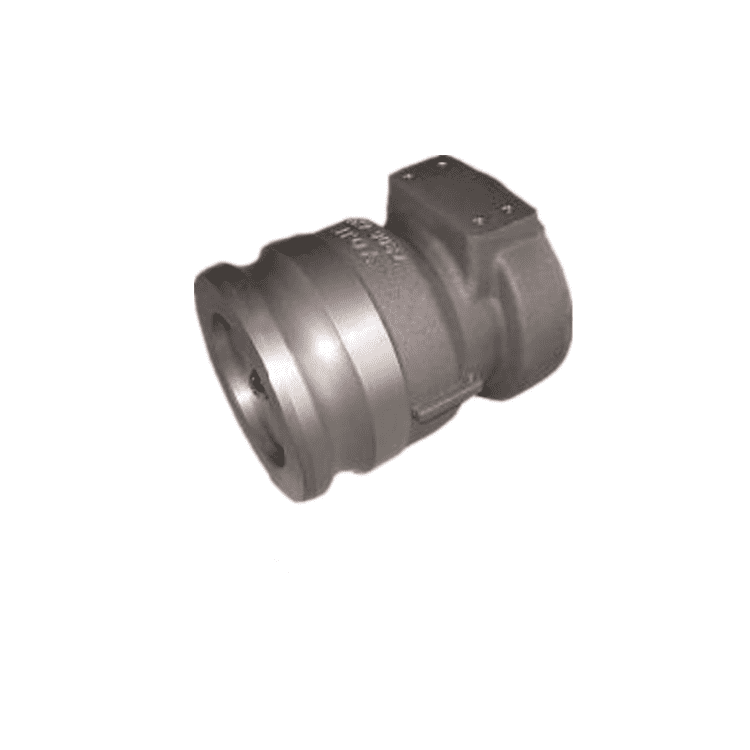

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for High Quality Axles For Sale - Teach you how to adjust to prevent brake weakness – MBP , The product will supply to all over the world, such as: Nepal, Iraq, azerbaijan, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.