Factory made hot-sale Trailer Air Suspension – What parts are usually use for super 36ton bogie axle repair – MBP

Factory made hot-sale Trailer Air Suspension – What parts are usually use for super 36ton bogie axle repair – MBP Detail:

The bogie suspension axle instead of mechanical suspension or air suspension. It can balance the two axles’ two sides in a very good condition. It normally use in west AFRICA countries like Nigeria, GHANA, Mauritania and middle eats like UAE, SAUDI ARIBA, KUWAIT, QATAR, YEMEN etc.

And we can see high mounting height bogie type and low height type which sometimes use for special lowboy trailers in Indonesia and Malaysia.

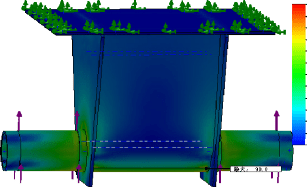

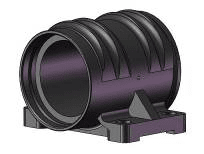

Mounting bracket: Primary function of mounting bracket: it connects the chassis and the axle system, and transmits all forces and moments between the wheels and chassis; Design of mounting bracket: the analyses with finite element are applied on simulation mold, and fatigue test and destructive test on the actual brackets; the unique box structure enables it to have excellent stiffness and stability.

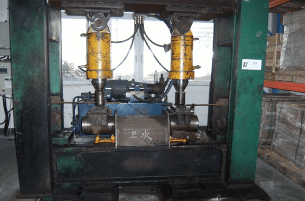

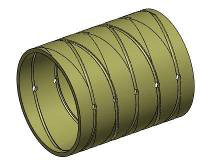

Steel plate spring assembly, as main stressed and buffered element, made of high quality leaf spring steel, has high mechanical performance, good impact strength and long service life, and satisfies the operating requirements of the suspension fully.

Width of steel plate spring for 25t bogie suspension:90mm, Width of steel plate spring for 36ton single suspension:120mm, The pieces of steel plate spring may be 17,18 and 19, and customized as demanded by client.

Steel plate springs of 120×19 pieces are usually used for 2×16 ton bogie axle in Saudi Market.

Balance pedestal, as main stressing element, made of QT500 casting iron, is applied with simulation analyses and has excellent tensile strength.

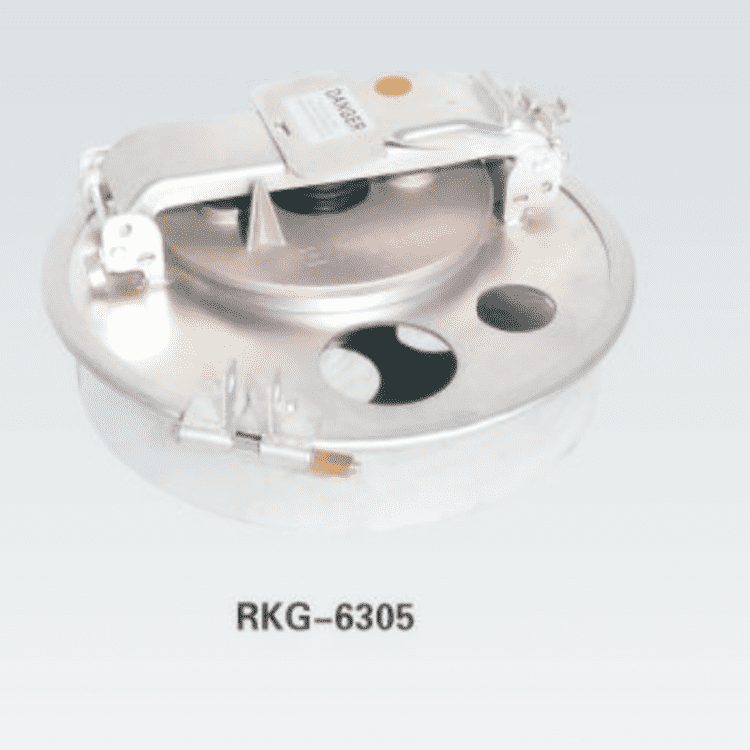

Steel plate spring saddle and shock pad are used for connecting plate spring and axle.

The saddle is made of high quality cast steel and formed as one block with high strength, safety and reliability;

Shock pad, made of high quality rubber material, has higher tensile strength and tear strength, as well as long life and perfect performance.

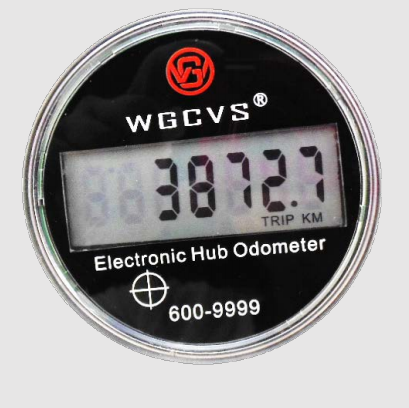

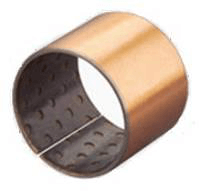

Equalizer bearing is classified as two types – compound bushing and brass bushing.

The compound bushing made of steel backing as base, bronze powder sintered in the middle, and modified polyformaldehyde (POM) on its surface; it is a self-lubrication bearing with oil storage pits.

Features of compound bushing type:

1.Good wear resistance and self-lubrication property;

2.Small friction coefficient, low wear rate, good resistance to shock, burning-in proofing, sintering and shaft neck friendliness.

3.Long lubrication interval, maintenance minimization, strong adaptability to harsh environment, and long service life;

4.High strength, corrosion proofing, small scale and light weight.

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.

Product detail pictures:

Related Product Guide:

Our advancement depends over the highly developed devices, excellent talents and continually strengthened technology forces for Factory made hot-sale Trailer Air Suspension – What parts are usually use for super 36ton bogie axle repair – MBP , The product will supply to all over the world, such as: Slovak Republic, Milan, Swansea, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!