China New Product Double Axle Trailer - Trailer axle brake Cam shaft repair kit for bpw fuwa with different length – MBP

China New Product Double Axle Trailer - Trailer axle brake Cam shaft repair kit for bpw fuwa with different length – MBP Detail:

| No. | Cam shaft (left) | Cam shaft (right) | Length(mm) | Fit for axle |

| 1 | 05.097.05.15.3 | 05.097.05.16.3 | 550 | Drum Square |

| 2 | 05.097.05.17.3 | 05.097.05.18.3 | 588 | Drum Square |

| 3 | 05.097.05.23.3 | 05.097.05.24.3 | 641 | Drum Square |

| 4 | 05.097.05.25.3 | 05.097.05.26.3 | 666 | Drum Square |

| 5 | 05.097.05.29.3 | 05.097.05.30.3 | 734 | Drum Square |

| 6 | 05.097.05.31.3 | 05.097.05.32.3 | 860 | Drum Square |

| 7 | 05.097.05.47.3 | 05.097.05.48.3 | 603 | Drum Square |

| 8 | 05.097.05.49.3 | 05.097.05.50.3 | 818 | Drum Square |

| 9 | 05.097.60.05.4 | 05.097.60.06.4 | 682 | Drum Round |

| 10 | 05.097.60.09.4 | 05.097.60.10.4 | 634 | Drum Round |

| 11 | 05.097.60.05.3 | 05.097.60.06.3 | 723 | Drum Round |

Trailer maintenance — changing brake pads

13m flatbed semitrailer, FUWA 13T triple axle 16t brake, four unequal leaf springs, with SORL 4m2sabs, the most common common lightweight Trailer configuration! In August of 17, it was idle for half a year and actually used for about 150000 kilometers for three years. It mainly runs in mountainous areas, but the number of kilometers is small, but there are many sharp curves and steep slopes in mountainous areas, and the brake is frequently used.

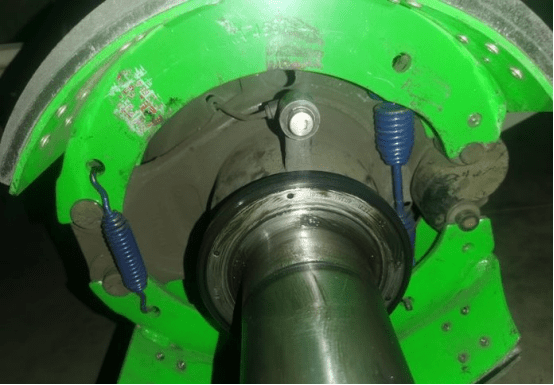

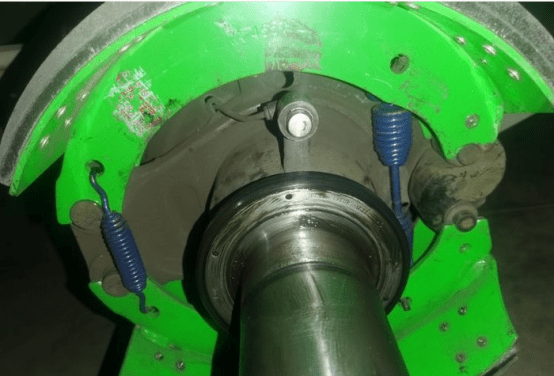

Last time, it was found that the trailer had a wheel brake stuck. The spring fell off and the spring was stuck in the brake shoe. The brake shoe could not return to position normally, and even the hoof iron was deformed!

The wear of the brake pads is close to the limit, and the brake shoes and springs are replaced. After the replacement, it was found that the paste temperature of the new wheel was higher than that of other wheels, although there was a serious single point drag tire of ABS. The thickness gap between the old and the new brake pads is too big, the new ones are too sensitive to respond. Only the emergency single wheel can release the brake to prevent overheating!

Is the new brake too smart??? No, it’s the other five rounds that can’t keep up with the rhythm. Loosening the single round is not the root of solving the problem. It’s right to make the other rounds work like this!

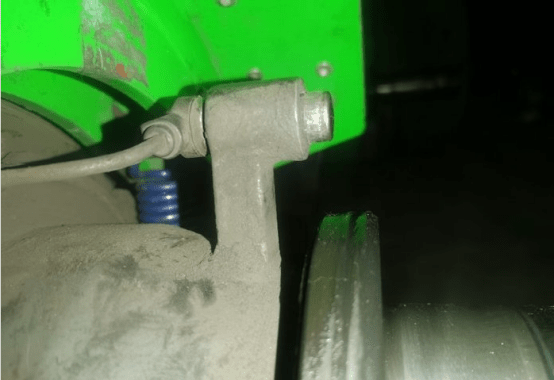

ABS sensor is the trailer maintenance need to pay attention to, must wipe clean the oil to push out, prevent ABS fault light after maintenance. ABS is good originally. After maintenance, the fault light is often on. Most of the sensors are not pushed out. The distance between ABS and gear ring is too big to sense the wheel speed! This problem will also happen to the main car!!!

The old oil in the wheel hub should be cleaned. The excessive old oil may be the ignition source after the brake overheats! The grease is only useful when it is installed on the bearing. It is impossible for the grease in the hub to run back to the bearing. It is not the gear oil with strong fluidity for soaking and lubrication!!!

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.

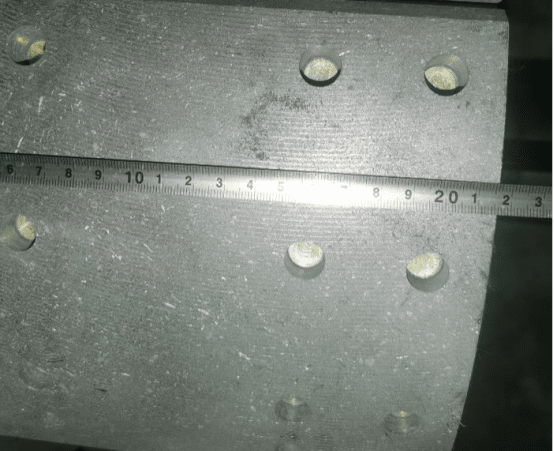

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for China New Product Double Axle Trailer - Trailer axle brake Cam shaft repair kit for bpw fuwa with different length – MBP , The product will supply to all over the world, such as: Malta, Jakarta, Georgia, we've got all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!