Cheap PriceList for Box Truck - BOTTOM VALVE, EMERGENCY FOOT VALVE, EMERGENCY CUT-OFF VALVE for fuel tank trailer – MBP

Cheap PriceList for Box Truck - BOTTOM VALVE, EMERGENCY FOOT VALVE, EMERGENCY CUT-OFF VALVE for fuel tank trailer – MBP Detail:

Usage

Bottom valves are designed for increased safety, durability and service performance. It is installed on the bottom of the tanker with flange connections, and the seals extend into the tanker. Utilizing stainless steel spring pressure with axial self-sealing to maintain emergency valve in closed state and operate opening and closing by transmission device. External shear groove can effectively absorb the energy from the pipe when the tanker is crashed down. The valve body cuts off from the shear groove and make the tanker and pipe separate to ensure perfect seals, avoid spillage and improve safety.

With perfect design, high flow, high drop to make the max benefit. Triple sealing on piston to reduce maintenance. Lightweight casting structure improves liquidity.

Feature

1.Aluminum alloy die-casting structure, anodized treatment

2.Hydrodynamic design minimize pressure drop for high flow rate.

3.Fixed plug structure, simple and practical

4.Shear groove automatically cut off under emergency to prevent spillage

5.Easy to be installed at compact place

6.Utilizing pneumatic control valve to control the opening and closing.

7.Used for many section tankers, separate loading and unloading for different fuel

8.According to EN13308 (NONE PRESSURE BALANCED), EN13316(PRESSURE BALANCED), flange meets TTMA standard.

Specification

| Nominal diameter | 3” or 4” |

| Working pressure | 0.6Mpa |

| Open method | Pneumatic |

| Temperature range | ‐20~+70℃ |

| Material | Aluminum alloy or steel |

Special surface treatment

The whole valve body is passed a special surface process to improve the anti‐corrosion.

Hydrodynamic body

Design and high lift poppet minimizes pressure drop to give maximum flow rate.

External shear groove

Meets the standard requirements to limit product spillage in the event of an accident.

Manual opening device

When need to emergency discharging, the pneumatic control is useless, it can be opened by manual way.

Easy‐Installment

The size of the valve is more smart, is suitable for the smaller space’s demand.

Easy servicing

Allows the air cylinder piston to be replaced without removing the valve from the tank pipe work.

Packaging & Delivery

packaging: carton, pallet & wooden case as per customer’s request.

Delivery time: within 15 days after payment

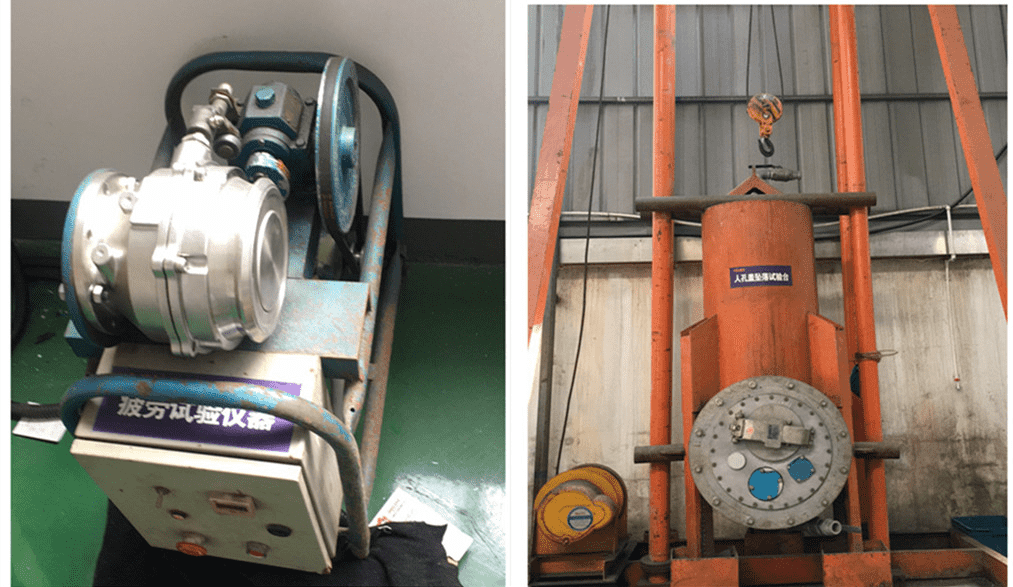

Fatigue and fall test

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.

Product detail pictures:

Related Product Guide:

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for Cheap PriceList for Box Truck - BOTTOM VALVE, EMERGENCY FOOT VALVE, EMERGENCY CUT-OFF VALVE for fuel tank trailer – MBP , The product will supply to all over the world, such as: Jordan, British, USA, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We will not live up to the historic opportunity of the times.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!